What Are Sugarcane Cups?

Sugarcane cups are made from a byproduct of sugarcane processing called bagasse. After the juice is extracted from the cane, what remains is this fibrous residue. For centuries, bagasse was considered waste. Now, it has found new life as a raw material for eco-friendly products like cups, plates, and containers.

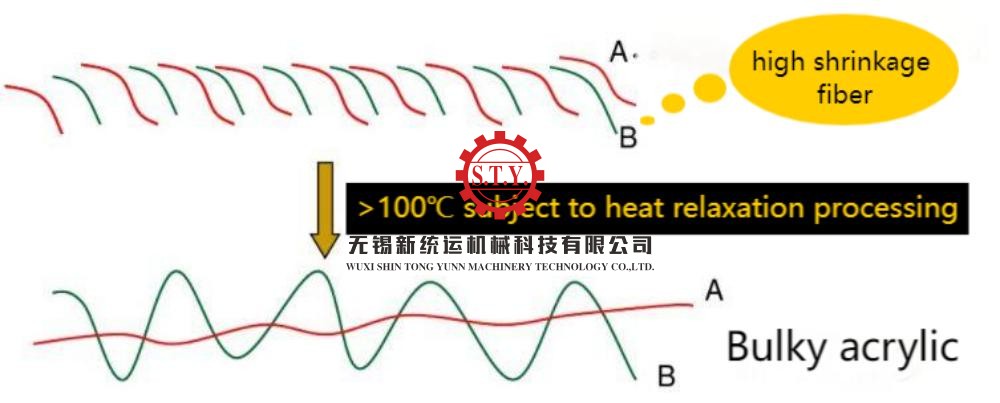

Bagasse is rich in cellulose, which makes it perfect for molding into sturdy, durable items. When treated with heat and pressure, it forms a strong, lightweight material that is both water and grease resistant. This makes sugarcane cups ideal for serving both hot and cold beverages, rivaling traditional plastic and paper cups in functionality, but without the environmental downsides.

Why Choose Sugarcane Cups?

1. Renewable Resource:

Sugarcane is a fast-growing crop that can be harvested multiple times a year, making it a highly sustainable raw material. Unlike fossil fuels used in plastic production, sugarcane regrows quickly, reducing environmental impact.

2. Biodegradable and Compostable:

One of the greatest advantages of sugarcane cups is their ability to biodegrade naturally. In a commercial composting facility, these cups break down completely within 60 to 90 days. Even in home composting systems, they decompose much faster than plastic or styrofoam, reducing the amount of waste that ends up in landfills or oceans.

3. Lower Carbon Footprint:

The production of sugarcane cups has a lower carbon footprint compared to plastic production. By using agricultural waste (bagasse), sugarcane cup manufacturers avoid the need for new raw material extraction. Additionally, the process of converting bagasse into products like cups is less energy-intensive than producing petrochemical-based plastics.

4. Safe for Hot and Cold Beverages:

Sugarcane cups are sturdy and resistant to moisture, making them suitable for all types of drinks. Unlike some biodegradable options that degrade with heat, sugarcane cups maintain their structure with hot beverages, offering a versatile and reliable choice for cafes, restaurants, and events.

5. No Harmful Chemicals:

Many conventional plastic cups contain harmful chemicals like BPA (bisphenol A), which can leach into beverages. Sugarcane cups, on the other hand, are chemical-free, making them a safer option for consumers and the environment.

Applications of Sugarcane Cups

The versatility of sugarcane cups has made them popular across a variety of sectors:

- Cafés and Restaurants: More eateries are opting for eco-friendly packaging to align with the growing demand for sustainability. Sugarcane cups are perfect for takeout coffee, juices, and smoothies.

- Events and Festivals: Large-scale events are often heavy users of disposable products. By switching to sugarcane cups, event organizers can significantly reduce waste and create a more environmentally responsible experience.

- Corporate and Educational Institutions: Businesses and schools striving to be more sustainable are introducing sugarcane cups in their cafeterias, vending machines, and events.

The Future of Sugarcane Cups

The increasing demand for sustainable packaging is driving more innovation in the bioplastics and eco-friendly product sectors. As consumers grow more aware of the environmental impact of their purchases, sugarcane cups represent an exciting opportunity to shift away from wasteful, single-use plastics.

As technology advances, the production processes for sugarcane-based products will continue to improve, making them even more affordable and widely available. Already, major cities and countries are considering or implementing bans on plastic cups and packaging, making alternatives like sugarcane cups not just a choice, but a necessity.